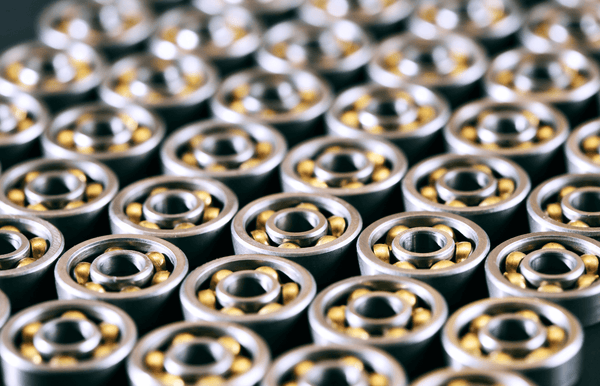

How Roller Skate Bearings are Made

Roller skate bearings are a crucial component of any roller skate setup, and their quality can greatly impact the skater's overall experience. One important factor in the manufacturing process of bearings is the quality of the steel used to create the ball bearings. The steel must be strong enough to withstand the load put on it during skating, but also soft enough to minimize friction and wear.

In order to achieve the optimal balance of strength and softness, bearing manufacturers typically use a type of steel called chrome steel. Chrome steel is a high-carbon alloy steel that has been specially heat-treated to make it harder and more durable. This type of steel is commonly used in roller skate bearings because it is able to withstand high loads and resist wear and tear over time.

However, even with the use of high-quality steel, roller skate bearings can still warp under load. This is because the weight of the skater, along with the force of their movements, can put significant pressure on the bearings. Over time, this pressure can cause the bearings to deform or warp, which can affect their performance and lifespan.

To address this issue, some bearing manufacturers have started using newer materials like ceramic or hybrid bearings that are more resistant to warping under load. Ceramic bearings are made from a mixture of ceramic materials and have a much higher hardness level than traditional chrome steel bearings. This means they are less likely to deform under load, resulting in a smoother and more consistent ride.

Inline skate bearings typically use a type of race known as a deep groove ball bearing race. This type of race is ideal for inline skate bearings because it can handle both radial and axial loads, which is important for the high-speed and high-impact nature of skating.

The Z and ZZ shields on inline skate bearings refer to the type of seal or shield that is used to protect the bearing from contamination. The Z shield is a single metal shield that covers one side of the bearing, while the ZZ shield is two metal shields that cover both sides of the bearing. The ZZ shield provides better protection against contamination, but it can also create more friction and reduce the speed of the bearing. In contrast, the Z shield provides less protection but allows for greater speed.

Other interesting facts about inline skate bearings include:

- The standard size for inline skate bearings is 608, which refers to the size of the inner and outer race. This size is also commonly used in other applications such as fidget spinners, electric motors, and bicycles.

- Inline skate bearings are typically made from steel, but they can also be made from ceramic, which can provide better performance and durability.

- Inline skate bearings are rated using the ABEC system, which measures the precision and tolerance of the bearing. However, many skaters believe that the ABEC rating is not the most important factor in determining the quality of a bearing, and that factors such as lubrication and cleanliness are more important.

- Inline skate bearings require regular maintenance, including cleaning and lubrication, to ensure optimal performance and longevity.

In conclusion, while the quality of the steel used in the ball bearings is critical to the performance and durability of roller skate bearings, it is not the only factor to consider. The design of the bearings, including the material used for the cages and the lubrication, also play a role in the overall performance of the bearings. Ultimately, it is important to choose bearings that are appropriate for your skating style and weight, and to regularly maintain and replace them as needed to ensure optimal performance.